The year 1969 gets a lot of column inches in history books. It marked the end of a tumultuous decade defined by cultural revolution and social upheaval.

Fast forward a bit and you’ll find 1971 was no fallow period either. Disney World opened, McDonald’s introduced the Quarter Pounder, NPR launched its first broadcast, and Barbie went to Malibu. The Nike Swoosh, Amtrak, FedEx, NASDAQ, and Starbucks all made their debuts. Greenpeace and Médecins Sans Frontières were founded to address humanitarian crises worldwide. The United Arab Emirates declared its independence, Swiss women got the right to vote and the US Supreme Court upheld bussing as a constitutional approach to integrating schools. The field of technology witnessed the invention of pocket calculators, floppy disks, the commercial microprocessor—even email.

1971 also witnessed a host of medical advances that changed thousands of lives for the better, from CT scans and soft contact lenses to the MMR vaccine. A quietly ambitious product called Co/Struc emerged at the same time, designed specifically for the medical field. Conceived by researcher Robert Propst with help from industrial designer Jack Kelley, Co/Struc made its mark on the healthcare industry by improving the work-life for everyone in patient care facilities.

Co/Struc designers Jack Kelley and Robert Propst in conversation, c. 1989.

“Areas of serious inadequacy and failure”

Backtrack to the late 1950s. Herman Miller’s president, DJ De Pree, was looking to expand the company’s offering following the success of products designed by Charles and Ray Eames, Alexander Girard, and George Nelson. The company’s bread and butter had become, essentially, chairs—but De Pree didn’t want to rely on one product category in the event of a sales downturn.

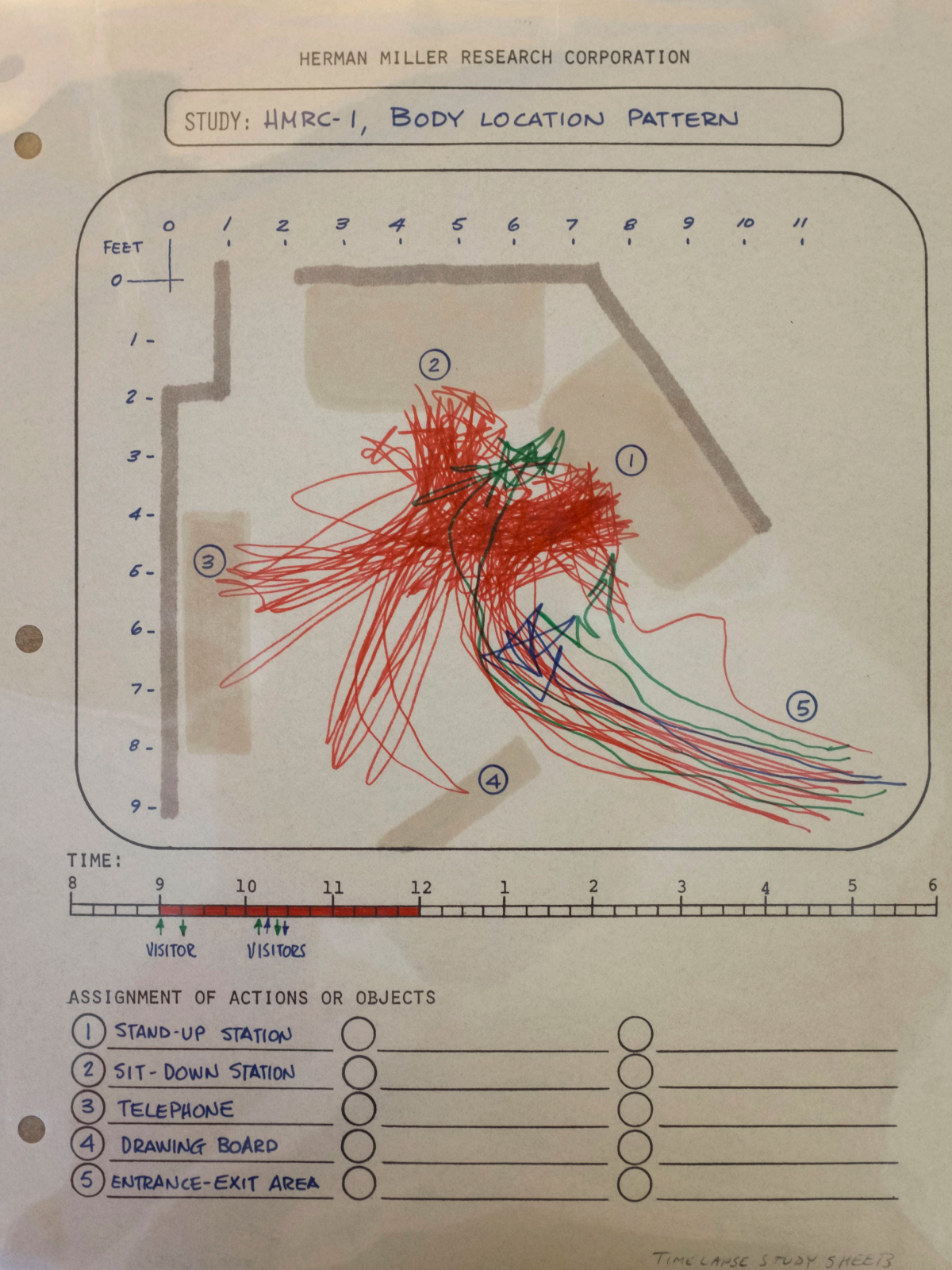

While attending the 1958 International Design Conference in Aspen, Colorado, De Pree’s chance meeting with an eccentric character named Robert Propst led Herman Miller to explore other areas outside of seating. Propst was a naturally curious individual, with an antenna for the truly innovative. A self-described “searcher,” he was known for his relentless pursuit of solving problems and an intolerance for wasting time and inefficiency. De Pree ended up appointing Propst as director of the newly-formed entity called Herman Miller Research Division (HMRD) in Ann Arbor, Michigan, to further explore his point of view.

The HMRD explored numerous fields of research, including, but certainly not limited to, furniture. In its first decade, Propst and his team embarked on nearly 30 projects, one of which studied human productivity and led to the development of Action Office.

In 1960, Propst slipped a disc in his back and landed in University Hospital in Ann Arbor. Cooped up in a hospital room, Propst—being Propst—couldn’t corral his restless mind. He appointed himself lead ethnographer and took note of everything he saw relating to hospital functions, closely watching how people moved and worked. The hospital staff were naturally a little paranoid to see someone writing down their every move without explanation. But Propst’s stint as a patient would be one of the best things to happen to clinicians and hospital staff.

Propst returned to his research department with hospitals on his mind—specifically their “areas of serious inadequacy and failure.” University Hospital eventually became a research partner for Propst’s ideas and concepts. He sold hospital management on the benefits of the Co/Struc components that were in development—designs for lockers, carts, and communication systems. He just had to convince Herman Miller management to take a risk and enter the healthcare business.

Early Co/Struc prototypes being tested within the patient area, c. 1966.

An early indicator of the potential of Propst’s research, Action Office—or “AO1”—hit the market in 1964. The design was later tweaked and evolved into the more successful AO2 in 1968. With this success came the discovery that its components could be applied to a variety of settings, particularly because of its modularity and adaptability. Later, the company returned to developing Co/Struc, which officially debuted in 1971 and launched Herman Miller into the healthcare market.

Co/Struc meets Action Office workstation meets Equa chair.

“There’s nothing like it”

At its simplest, Co/Struc is a system of containers, frames, carts, and rails. It was the first instance of a movable, modular system designed specifically for healthcare settings. According to Propst, its modularity was intended “to solve a series of interrelated problems with elements that produce greater results and influence by their collective impact.”

During his time leading the research division, Propst established nine criteria that formed the basis for both Action Office and Co/Struc. These nine criteria not only allow for adaptability, but also provided a theoretical foundation for the success of these products, making Co/Struc hard to duplicate without considering the principles behind it.

Robert Propst, c. 1989.

Propst’s Nine Criteria

- Forgiving: solutions that allow for change

- Coherent: solutions with elements that work together and integrate with other systems

- Process forwarding: solutions that make it easy and intuitive to perform tasks

- Modular limited: solutions that require fewer components but have maximum function and capability

- Open-ended: solutions that respond to new situations and needs without disrupting visual continuity

- Readily available: solutions that continue to give you what you need when you need it over time

- Replaceable: solutions with components that are easy to disassemble and upgrade without losing your initial investment

- Progressively enterable: solutions that can be updated at your own pace

- Facility renewing: solutions that help convert existing facilities to new uses and/or bring fresh capabilities to a facility

To bring a hospital up to Propst’s standards, Co/Struc needed to solve six key problem areas—sanitation, obsolescence and failure, customized service, transport and supply, human use, and appearance—then apply his nine universal criteria to create the kind of system that healthcare facilities could benefit from.

Starting with sanitation, traditional materials used for furniture (and the way in which they were put together) made most existing furniture—such as a wood bed frame—difficult, if not impossible, to sanitize using “reasonable and routine procedures.” Co/Struc is separable, seamless, cornerless, and drainable. All surfaces, as well as individual components that can be lifted and hung on the wall are made accessible for cleaning. Waste collection frames and carts were even made washable. “As nurses, we were ecstatic,” reports Janet Ziegler, an RN, MN, MBA, EDAC, and retired nurse leader. “Easy to clean, organize, move … Wow!”

At its essence, every element of Co/Struc is user-friendly and doesn’t require extensive training to reconfigure—which comes into play quite often considering that every patient, clinician, and clinical department has different needs. Built-in, one-size-fits-all equipment is inherently inflexible. Co/Struc solves that problem with its intrinsic adaptability: Components can be reconfigured and readjusted to meet a variety of needs. For example, the rails are height-adjustable and can be mounted to walls. Likewise, carts provide a place for mobile hangers.

“This product can go anywhere in a hospital,” explains Jim Wright, Herman Miller’s now-retired healthcare sales manager. “If somebody didn’t need storage in an operating room, that same component could go downstairs and be used in the emergency department. [It didn’t require] a lot of money to make changes.” Co/Struc eventually made its way into laboratories, pharmacies, and administrative offices too.

Components that can be individually removed and replaced also counter the ever-present issue of obsolescence. Healthcare environments are notorious for constant change, which means equipment becomes outdated and less aesthetically pleasing well before it fails. “Nobody had anything like it … I could take a C-drawer, and if something ever happened to it, the customer could replace that drawer,” says Wright. “That was [Propst’s] mandate: a true system.”

There’s also an issue of supply and demand. Hospitals can be a run-fetch-deliver situation, and on-the-move staff will inevitably have urgent material needs. Propst planned his Co/Struc system to handle the complete cycle of materials management. Drawers and carts can be used as transport containers and loaded with supplies to be distributed wherever needed.

Co/Struc and materials management, c. 1972.

Crucially, Co/Struc was designed with appearance in mind: a bright, clean design with drawers available in a selection of colors for visual appeal (beauty) and color-coding (utility). The issue of waste and soiled linens is not only a concern for sanitation—it can make for a ghastly image. Co/Struc provided nice-looking closed containers and hanger frames to store contaminated items. Propst used the term “visual schizophrenia” to describe the typical hospital environment for its failure to create a space that’s both appealing to patients and houses all the technical and service functions.

Overall, Co/Struc introduced a new standard of performance for healthcare furnishings: Attractive. Sanitizable. Washable. Separable. Replaceable. Self-hanging. Self-stacking. Portable. Cushioned to absorb impact.

Co/Struc in the exam room, c. 1975.

Nothing ventured, nothing gained

Herman Miller enjoyed a spike in revenue at the end of the 1960s and into the 1970s due to the success of Action Office and Co/Struc. The transformation from an objects company into a systems company took sales from $20 million to over $230 million. This is no minor feat and it would not have been possible without Herman Miller trusting Propst and taking an ambitious risk.

“Propst was suggesting we should go into hospitals where we had no experience and knew nothing,” says Joe Schwartz, who oversaw the marketing and sales department at Herman Miller from 1954 to 1986. “But Propst was a very effective communicator, so he got permission to keep working on the development and the research.”

And it paid off.

It’s dizzying to consider all the change in the last year, let alone the last 50. 1971 was the very beginning of a sprint in terms of new technologies that transformed the way people and industries function. And throughout this era of change, Co/Struc has been a constant. Its design principles, radically different when Propst first conceived them, have retained their modern spirit. The system’s modularity and reconfigurability have sustained its relevance—with minor tweaks and iterations over time, it’s still in use and demanded by healthcare professionals to this day.

“When you have continuous improvement, you need an environment that can support continuous change easily,” says Roger Call, who ended his 35-year career at Herman Miller in 2020 as Director of Healthcare Architecture and Design. “Which just by way of happenstance is what Action Office and Co/Struc are all about, thanks to Bob Propst. Because our customers are going through continuous change, they can appreciate having the ability to redo, reconfigure, and repurpose facilities.”

Notes

1. Herman Miller, Co/Struc: A Coherent Structures System for Hospitals, Herman Miller, Inc. 1967

2. Herman Miller, Solution Essay: Lean Lives in Adaptive Settings, https://www.hermanmiller.com/content/dam/hermanmiller/documents/solution_essays/se_lean_lives_in_adaptive_settings.pdf. 2016, 4–6