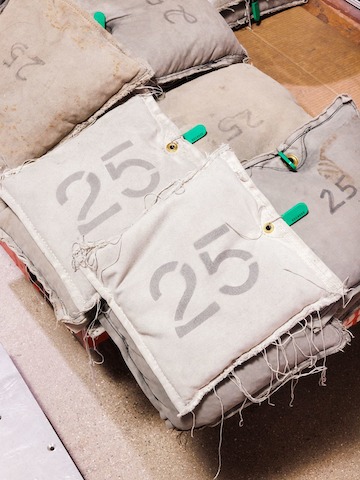

240 pounds of static weight sit ready for the back durability test.

In 1958, at the urging of Charles and Ray Eames, George Nelson and Herman Miller owner D.J. De Pree created a space where designers could experiment on product prototypes and testing. More than six decades later, the Test Lab looks different than when it first opened. What was once an old repair shop chock-full of mechanical devices (cables, pulleys, weight canisters—even pneumatic components) is now a precision laboratory the size of an airplane hangar, with technologically advanced machines that can measure velocity and impact to the nth degree.

The lab sits at the heart of the making zone at the Design Yard in Holland, Michigan—flanked by the makers space and product design studio. It is what might be described as a tinkerer’s laboratory—scratch that, a tinkerer’s gigantic, gleaming, heavy machinery-laden playground. The floors are marked with safety tape and red and green lights flicker on and off, signaling a secret machine language.

The rhythm of the Durability Test machines fills the air. Weighted bags drop unceremoniously into the seat of a chair. Armpads bob under increasing and decreasing pressure. Casters spin for days on end—all in the name of the science behind the design.

Technicians conduct some 2,500 different tests, on products ranging from task chairs to height-adjustable desks to panel and benching systems. Load-bearing and durability tests recreate worst case scenarios: armrest-perchers, backrest leaners, feet tuckers. Increased weight is added to hung shelves until they collapse. Machines perform backbreaking stretches on furniture. Wear simulation deploys robotics to recreate months, years, or even a lifetime of use in a shortened time frame. The technicians will often reverse-engineer by recreating a failure. And if you ask many of them, the failure is where the fun lies. “Chairs get the glory, but panel systems, benching systems get load-bearing tests, and those are much more labor-intensive—up to 4–5,000 pounds of dead weight on a system,” says engineer Kyle Wright, testing services manager for the lab.

In a corner of the lab, tucked away from the constant humming motion, techs perform chemical tests with an assortment of beakers: soda, sweat, disinfectant. There are chambers that simulate heat, humidity, or cold—an important test when products are shipped in any manner of weather. Every problem that arises—or potentially could—is treated to the scientific method and rigorously analyzed. Following testing, the lab team collects raw data to make a determination about whether a design passes or fails.

BIFMA (Business and Institutional Furniture Manufacturers Association) guidelines set the industry standard for product performance—though Herman Miller products often go above and beyond the requirements. Take the back durability test—or the “lean back”—which has a requirement of 120,000 cycles of reclining, with a force of 75 to 100 pounds. Herman Miller performs 1,000,000 cycles. Why? It’s all about the warranty. Many of the products tested feature a 12-year warranty: 12 years, yes, but also for 24 hours a day, seven days a week, 365 days a year. For the technicians, it goes even further than that: Their integrity is at stake. “We’re the gatekeepers of quality,” says Wright.

To understand the significance of quality and integrity at the Test Lab, it’s important to look at its origins. Nelson’s first furniture collection for Herman Miller in 1948 included an accompanying catalog that laid out the foundation for several principles in its foreword, including quality (a good precursor to what would become the Test Lab just a decade later).

“What you make is important,” wrote Nelson. “Herman Miller, like all other companies, is governed by the rules of the American economy, but I have yet to see quality of construction or finish skimped to meet a popular price bracket, or for any other reason.”

In 1978, design critic Ralph Caplan gave an address to Herman Miller’s President’s Club meeting on the subject of “Eames and quality.” (The lecture would later be printed as an essay, “Doing Quality.”) He suggested to make a design that is “as good as it could be,” an idea paraphrased from one of the Eames Office staff designers, Peter Pearce, any creative act must also include a “willingness to fail.”

The "Swinging impact" cart features a weighted wrecking ball.

All the tests that bend, spin, prod, poke, bob, drop, and douse these products help to fulfill the company’s robust warranty—and then some. While some chairs might see a different sitter every day, all day, other chairs might be passed along through generations. “We’re trying to make something that can hold up,” says Curt Vanduren, senior Test Lab technician. “We hear, ‘Why does the chair cost so much?’ And I tell them, you have no idea what goes into that chair. And what’s expected of that chair throughout its lifetime.”

Wright says that a product might take three to five years to launch—with six to 10 different builds, each subject to trials. Some of the tests are straightforward—and some are decidedly not. He recalls a particularly memorable systems test many years ago that included office panels and partitions. “We hooked up everything with hydraulics, to simulate shelves and a work surface being pulled down,” says technician Steve Arendsen. “Taking that to failure—it pretty much exploded. I mean, panels were flying.”

Technician Steve Arendsen finds a moment of peace and quiet in the Test Lab in his office—a converted humidity shock chamber.

Because these tests can often include the—ahem—destruction of products, early development often includes rudimentary materials. “We see chairs through the whole process, starting at cardboard and duct tape,” says Vanduren. And it’s not just the early designs that get beat up—every stage in the product’s life span gets a test. For the technicians who have come to revere these pieces, it hurts a bit. As Arendsen says, “It’s a shame to see a nice Aeron go up in flames.”

“We’re the gatekeepers of quality.”

—Kyle Wright, Testing Services Manager